Product Overview

The crane brakes are widely used for deceleration or braking in mechanical drive devices across various industries, including lifting, metallurgy, transportation, mining, ports, docks, and construction machinery. Crane brakes can be roughly categorized into several types: drum brakes, disc brakes, windproof brakes, and safety brakes.

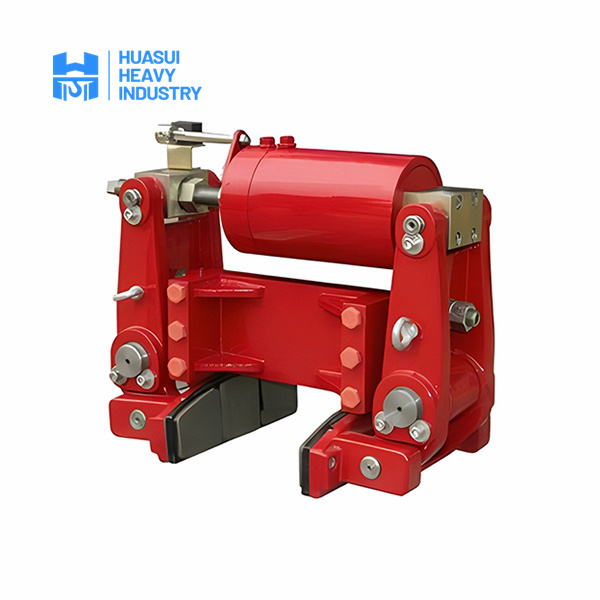

Electric Hydraulic Drum Brake

Main features

- There are two types of brake pad installation: riveted and inserted (please specify when ordering).

- The main pivot points are equipped with self-lubricating bearings, providing high transmission efficiency and long service life, requiring no lubrication during use.

Standard-Compliant The installation dimensions and braking torque parameters of this series of brakes comply with the JB/ZQ4388-1997 standard, and the technical requirements conform to the JB/T6406-2006 standard.

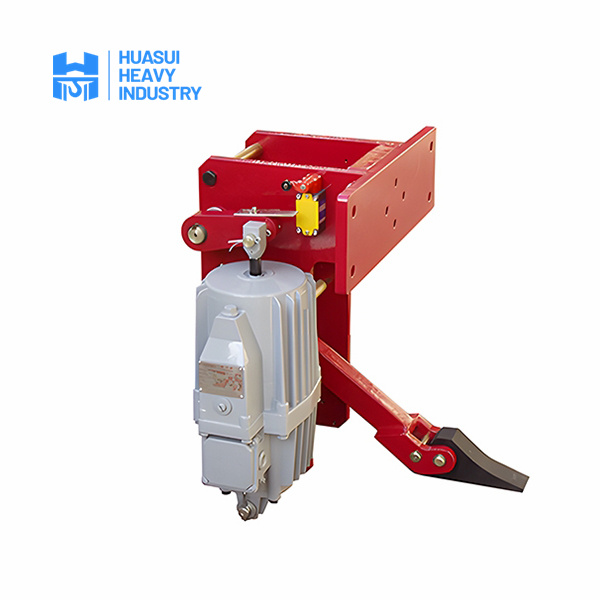

Disc Brake

The electric windproof iron wedge brake is mainly used as a windproof brake for various rail-mounted cranes operating outdoors, such as gantry cranes, portal cranes, and unloading bridges at ports, docks, and railways. It can also work in conjunction with anchoring devices and windproof cables to provide safe windproof braking measures for cranes when they are not in operation. Main Features

- Equipped with a release limit switch for interlock protection.

- The main pivot points are equipped with self-lubricating bearings, providing high transmission efficiency, sensitive and reliable actions, and long service life.

- Features a manual-release torque for easy maintenance.

- Matches with the Ed reset spring pusher, offering excellent performance, good sealing properties, and a high protection level for the casing.

- The spring reset function prevents the pusher from becoming unresponsive and ensures the wedge block resets promptly after a power outage.

- The wedge block undergoes special processing, providing a high friction coefficient and good anti-corrosion performance.

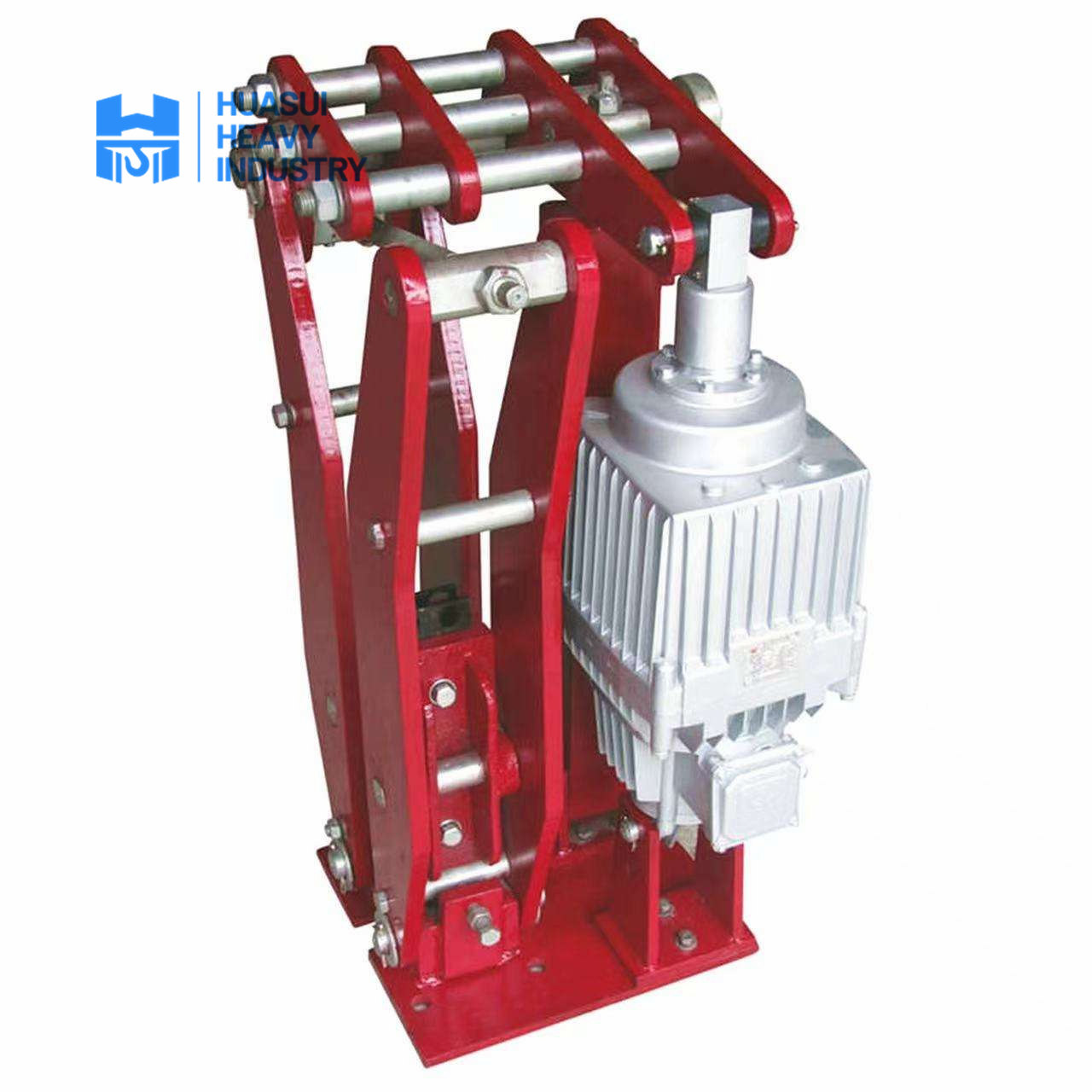

Hydraulic Wheel Brake

The hydraulic wheel-side brake is mainly used for windproof braking in the working state and auxiliary windproof braking in the non-working state for medium and large cranes and port handling machinery used outdoors in ports and docks. Wheel-side brakes are generally only used on driven wheels and provide direct braking, effectively preventing the braked wheels from rolling or shifting under wind forces. The braking effect is enhanced and more economical if windproof brakes are also used on the drive wheels’ high-speed shafts. Main Features

- Normally closed design, with the hydraulic station applying force to the disc spring to release, ensuring safety and reliability.

- Equipped with a limit switch for interlock protection.

- Asbestos-free friction pads offer stable performance, and the installation structure is novel and unique, making replacement convenient

- Corrosion-resistant design, with all fasteners and pins made of stainless steel.

Operating Conditions

- Ambient temperature: -5°C to +40°C.

- Working pressure: 8 MPa.

- For outdoor environments exposed to rain, snow, or corrosive gases and media, corrosion-resistant products should be used.

Electromagnetic Safety Brake

The AP electromagnetic self-braking safety brake (also known as the electromagnetic fail-safe brake) features a normally closed design and uses a wedge self-locking structure for braking. It is equipped with an action monitoring switch for interlock protection and fault feedback, ensuring safety and reliability. The brake is sensitive and has a short braking time. It is compact, lightweight, easy to install and use, and saves space. Product Features

- Due to its unique braking principle, it does not require an external power source, making it more economical compared to similar brake products.

- The unique mechanical structure principle ensures that the braking force is directly proportional to the load force: the greater the load force, the greater the braking force, ensuring safety and reliability.

- Its compact structure allows for a lightweight design compared to other brake products of the same specification.

- It provides true fail-safe braking by performing safety braking when the transmission system fails or malfunctions.

- The electromagnetic mechanism uses low-voltage DC control, high-voltage excitation, and low-voltage maintenance, enhancing safety and lifespan while achieving energy savings and reduced consumption.

Standard-Compliant Product technical requirements apply to the JB/T10917-2008 caliper disk crane brake standard.