Product Overview

Buffer is configured in the crane metal structure at the end of a safety device, has to absorb the kinetic energy of the collision of the operating mechanism to slow down the impact of the role. The most commonly used buffers for cranes are polyurethane buffer, hydraulic buffer, spring buffer and rubber buffer. In addition composite buffer, damping buffer and gas-hydraulic buffer can also be used for cranes.

Polyurethane Buffer

Working temperature: -20~60℃

Applicable buffer type: high and low frequency impacts

Recommended service life: 1 year

Application: Overhead and gantry cranes, crane trolleys, slow-speed elevators, etc.

Advantages

- Large energy absorption, good cushioning performance. The cushioning process can consume 40% of the energy, 60% of the energy is stored and finally released, moderate rebound, compressibility and good resilience.

- Light weight

- Low cost work is a soft collision, no noise, no sparks, often used in explosion-proof place

Disadvantages

Not suitable for metallurgical environment, Poor resistance to ultraviolet light.

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) | weight(kg) |

|---|---|---|---|---|

| 1 | 0.265 | 60 | 28 | 0.24 |

| 2 | 0.502 | 75 | 42 | 0.34 |

| 3 | 0.98 | 94 | 66 | 0.65 |

| 4 | 1.96 | 120 | 103 | 1.3 |

| 5 | 4.019 | 150 | 169 | 2.3 |

| 6 | 7.85 | 188 | 265 | 5 |

| 7 | 15.7 | 240 | 414 | 9.5 |

| 8 | 25.732 | 240 | 675 | 15 |

Hydraulic Buffer

Applicable buffer type: high and low frequency impacts

Loadable speed: <3.5m/s

Recommended service life: 3 years

Application: Can be used for heavy cranes, port machinery, elevators, etc.

Advantages

- High suction capacity

- Uniform buffer

- No special requirements for use environment

- 100% reset after unloading

Disadvantages

Overall product life is limited by spring life

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) | weight(kg) |

|---|---|---|---|---|

| 1 | 4 | 50 | 80 | 18 |

| 2 | 10 | 70 | 150 | 40 |

| 3 | 25 | 80 | 315 | 90 |

Spring Buffer

Working temperature: -20~60℃

Applicable buffer type: high and low frequency impacts

Loadable speed: <2m/s

Recommended service life: 3 years

Application: Heavy duty cranes, port machinery, mining machinery

Advantages

High wind sand and other special working conditions, the product performance is not affected

High temperature resistance

Corrosion resistance

No aging failure phenomenon

Stable operation

Can adapt to the harsh environment

Disadvantages

Low energy absorption, High rebound force.

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) | weight(kg) |

|---|---|---|---|---|

| 1 | 0.16 | 80 | 5 | 11 |

| 2 | 0.4 | 95 | 8 | 19 |

| 3 | 0.63 | 115 | 11 | 26 |

| 4 | 1 | 115 | 18 | 36 |

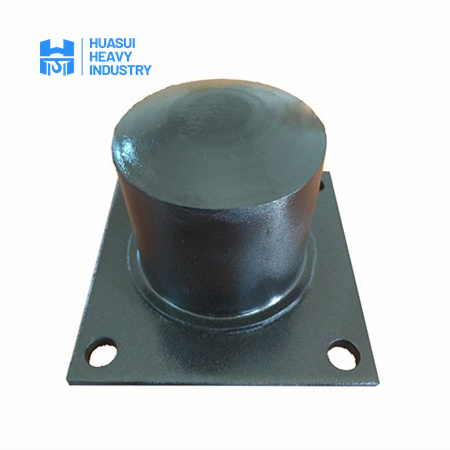

Rubber Buffer

Loadable speed: 0.9m/s

Recommended service life: 20 years

Application: Heavy duty cranes, port machinery, mining machinery

Advantages

- Simple construction

- Low cost

- 30%~50% of kinetic energy consumption and internal friction in the buffering process, small rebound.

- Work is soft collision, no noise, no sparks

- Can be used in special explosion-proof places

- High wind and sand and other special working conditions, product performance will not be affected

- No aging failure phenomenon

- Stable operation

- Can adapt to the harsh environment

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) | weight(kg) |

|---|---|---|---|---|

| 1 | 0.1 | 22 | 16 | 0.36 |

| 2 | 0.63 | 40 | 50 | 2.13 |

| 3 | 2.5 | 63 | 118 | 6.5 |

| 4 | 4 | 80 | 200 | 12 |

| 5 | 10 | 100 | 300 | 25 |

| 6 | 16 | 112 | 425 | 34 |

| 7 | 20 | 125 | 500 | 18.2 |

| 8 | 25 | 140 | 630 | 64.8 |

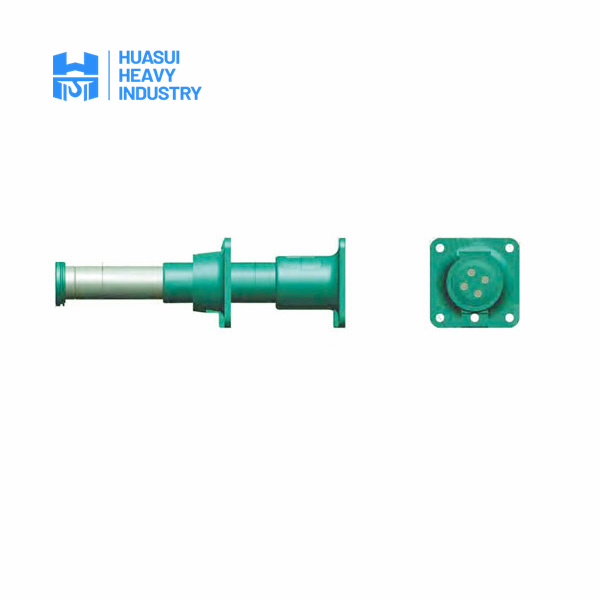

Composite Buffer

Working temperature: -20~60℃

Material: polyurethane, spring, seamless steel

Applicable buffer type: high and low frequency impacts

Loadable speed: 0.9m/s

Suggested service life: 3 years

Application: Can be used for cranes and crane trolleys

Advantages

High energy absorption

UV resistant

Corrosion resistant

No aging failure

High impact strength

Stable operation

Adaptable to harsh environments

Disadvantages

Not resistant to high temperature

Slow rebound

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) |

|---|---|---|---|

| 1 | 15 | 140 | 400 |

| 2 | 19 | 150 | 460 |

| 3 | 35 | 150 | 650 |

| 4 | 20 | 80 | 500 |

| 5 | 25 | 100 | 500 |

| 6 | 42 | 120 | 700 |

| 7 | 20 | 240 | 520 |

Damping Buffer

Working temperature: -70~80℃

Material: damping fluid, seamless steel

Applicable buffer type: low frequency impact

Loadable speed: <1.5m/s

Recommended service life: 15 years

Application: Anti-collision cushioning for heavy cranes, harbor machinery and other large equipment. Can also be used in the railroad transportation industry and metallurgical industry

Advantages

- High energy absorption

- High (low) temperature resistance

- Corrosion resistance

- No aging failure

- High impact strength

- Stable operation

- Adaptable to harsh environments

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) |

|---|---|---|---|

| 1 | 0.7 | 35 | 40 |

| 2 | 1.2 | 40 | 60 |

| 3 | 2.6 | 50 | 100 |

| 4 | 4.8 | 65 | 150 |

| 5 | 9.6 | 80 | 230 |

Gas-Hydraulic Buffer

Material: hydraulic oil, high pressure nitrogen, seamless steel

Loadable speed: <3.3m/s

Recommended service life: 5 years

Application: Heavy crane, port machinery, mining machinery, elevator

Advantages

Large stroke

High energy absorption

Uniform cushioning

Loadable speed <3.3m/s

No special requirements for the use of the environment

100% reset after unloading

Disadvantages

Large size and weight of single product

Parameters

| Item | buffer capacity(kJ) | stroke(mm) | buffering force(kN) | weight(kg) |

|---|---|---|---|---|

| 1 | 32 | 100 | 400 | 38 |

| 2 | 64 | 200 | 400 | 44 |

| 3 | 96 | 300 | 400 | 57 |

| 4 | 128 | 400 | 400 | 71 |

| 5 | 160 | 500 | 400 | 80 |

| 6 | 192 | 600 | 400 | 90 |

| 7 | 210 | 700 | 375 | 107 |

| 8 | 224 | 800 | 350 | 118 |

| 9 | 238 | 900 | 330 | 128 |

| 10 | 260 | 1000 | 325 | 139 |